The Weller Technology

is an innovative and internationally patented process for the manufacturing of rotating electrical machines.

Production Technology

The motors can only be partially manufactured using conventional production technology.

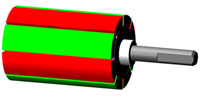

Rotor

The rotor is largely identical in construction to the current standard both as a squirrel-cage rotor for the asynchronous motor and as a magnetic pole armature for the synchronous motor.

The only thing that needs to be taken into account is that the shell surface must be homogeneous when using the unwinding system.

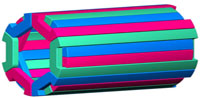

Excitation winding

Familiar manufacturing technology is not suitable for the winding process.

A new machine must be developed and built for this purpose. This machine has to produce the coil structure with self-bonding wire very precisely in hot conditions.

The windings are intended to be applied from 3 sides simultaneously.

After the winding process the excitation winding is shaped. This also requires the development and manufacturing of a new machine,